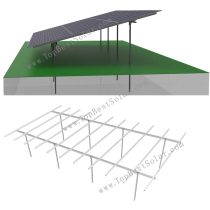

Solar Pile ground Mounting system

Model: SPC-PGM

Installation Site: open area

Material: SUS304, 6005-T5 Alum &hot dip galvanized steel

Tilt Angle: 0° to 60°

PV Module: Framed, Frameless

PV Orientation: Portrait, Landscape

Wind Load: 60 m/s

Snow Load: 3.2 KN/M2

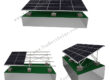

The solar ground mounting system is widely applicable to residential and commercial projects on solid ground. It is also compatible with level ground.

And the Solar double-pillar ground Mounting system is also suitable for large-scale ground power plants in various terrains.

Features of the solar ground mounting system

Our solar ground mounting can work under any ground and soil conditions

Keep level when adjusting the panel to suit various terrains.

Pre-assembled Components Save Onsite Installation time

Solution design case by case, most components pre-assembled in factory, no onsite cut and drill request, saving the onsite installation time and cost.

Structure Configuration Multi-Options

Single or double embrace bars structure configuration availableto meet varied projects requests.

Flexibility and Adjustability

The structure can be adjusted with some tolerance with east-west, west-south and south-north directions, assuring flexible on-site installation to achieve best yield for solar modules.

Further more,Our Solar ground Mounting adopts open carbon steel cross section as support with pile driving equipment.

So the installation speed can be increased by 50% compared with that of screw which greatly saves installation time and makes installation easier.

Last but not least,our Solar Pile ground system is designed to be quickly assembled under any field conditions. Compared with other solar ground mounting systems.

This solar ground system occupies a small footprint, has strong compatibility, reduces the amount of stringers used, but does not affect the firmness, and can also reduce your installation time and cost.

Welcome to get more details of our Solar ground Mounting system (Model:SPC-PGM) for your renewable energy project from www.TopBestSolar.com

Installation Step:

- Check the drawing to understand the distance of each pile driving position.

- Use a pile driver to drive the pile, drive about 1500mm, the opening of the column is unified to the right, and the double bar holes face back and forth.

- Pull the horizontal line reference to continue to drive the pile, use the laser to check the level.

- Lock other column and beam joint assemblies on the column.

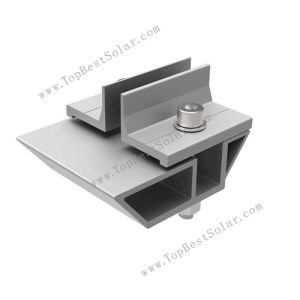

- Install C steel.Continue to install C steel and secure it with connectors. andhang the aluminum clamp assembly on the c steel, and do not lock it first.

- The rail through aluminum clamp assembly, locking bolts fixed.

- Fix the solar panels with panel clamps, 6 pieces per module.

- Use the Rubber to separate each two panels.

- This project needs to be installed back to back. The installation sequence of the other side is the same as that of the previous side.

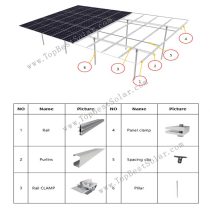

| Components List | ||||

|

Item |

Product Code |

Picture |

Produce name |

Material |

| 1 | SPC-R-120 | Aluminum rail | AL6005-T5 | |

| 2 | SPC-CR-T2-140*70*20 | C Steel Purlins | S350GD-ZM | |

| 3 | SPC-RC-CZ76 | Rail Clamp | AL6005-T5 | |

| 4 | SPC-SP-R140*70*20 | Beam Connector | S350GD-ZM | |

| 5 | SPC-RO-NW163 | Column Connector | S350GD-ZM | |

| 6 | SPC-SQ65*60-L2600 | Front Pillar | S350GD-ZM | |

| 7 | SPC-SQ65*60-L3640 | Back Pillar | S350GD-ZM | |

| 8 | SPC-R-S12 | Seal Rubber | EPDM | |

| 9 | SPC-SQ50-40 | Panel Clamp | AL6005-T5 | |

- Description

-

The solar ground mounting system is widely applicable to residential and commercial projects on solid ground. It is also compatible with level ground.

And the Solar double-pillar ground Mounting system is also suitable for large-scale ground power plants in various terrains.

Features of the solar ground mounting system

Our solar ground mounting can work under any ground and soil conditions

Keep level when adjusting the panel to suit various terrains.

Pre-assembled Components Save Onsite Installation time

Solution design case by case, most components pre-assembled in factory, no onsite cut and drill request, saving the onsite installation time and cost.

Structure Configuration Multi-Options

Single or double embrace bars structure configuration availableto meet varied projects requests.

Flexibility and Adjustability

The structure can be adjusted with some tolerance with east-west, west-south and south-north directions, assuring flexible on-site installation to achieve best yield for solar modules.

Further more,Our Solar ground Mounting adopts open carbon steel cross section as support with pile driving equipment.

So the installation speed can be increased by 50% compared with that of screw which greatly saves installation time and makes installation easier.

Last but not least,our Solar Pile ground system is designed to be quickly assembled under any field conditions. Compared with other solar ground mounting systems.

This solar ground system occupies a small footprint, has strong compatibility, reduces the amount of stringers used, but does not affect the firmness, and can also reduce your installation time and cost.

Welcome to get more details of our Solar ground Mounting system (Model:SPC-PGM) for your renewable energy project from www.TopBestSolar.com

- Installation

-

Installation Step:

- Check the drawing to understand the distance of each pile driving position.

- Use a pile driver to drive the pile, drive about 1500mm, the opening of the column is unified to the right, and the double bar holes face back and forth.

- Pull the horizontal line reference to continue to drive the pile, use the laser to check the level.

- Lock other column and beam joint assemblies on the column.

- Install C steel.Continue to install C steel and secure it with connectors. andhang the aluminum clamp assembly on the c steel, and do not lock it first.

- The rail through aluminum clamp assembly, locking bolts fixed.

- Fix the solar panels with panel clamps, 6 pieces per module.

- Use the Rubber to separate each two panels.

- This project needs to be installed back to back. The installation sequence of the other side is the same as that of the previous side.

- BOM

-

Components List Item

Product Code

Picture

Produce name

Material

1 SPC-R-120 Aluminum rail AL6005-T5 2 SPC-CR-T2-140*70*20 C Steel Purlins S350GD-ZM 3 SPC-RC-CZ76 Rail Clamp AL6005-T5 4 SPC-SP-R140*70*20 Beam Connector S350GD-ZM 5 SPC-RO-NW163 Column Connector S350GD-ZM 6 SPC-SQ65*60-L2600 Front Pillar S350GD-ZM 7 SPC-SQ65*60-L3640 Back Pillar S350GD-ZM 8 SPC-R-S12 Seal Rubber EPDM 9 SPC-SQ50-40 Panel Clamp AL6005-T5 - Video

-

- Leave Message

-