A corrugated metal roof is celebrated for its longevity, weather resistance, and low maintenance—but its performance hinges on one often-overlooked component: the metal roof clip. Choose the wrong clip, and you risk costly issues like panel warping, leaks, or even roof failure in extreme weather. Whether you’re a commercial contractor, a residential roofer, or a DIY homeowner, selecting the right corrugated metal roof clip series is the key to a secure, long-lasting roof. This guide breaks down everything you need to know to choose, install, and benefit from the best metal roof fixtures on the market.

What Are Corrugated Metal Roof Clips, and Why Do They Matter?

Metal roof clips are specialized fasteners designed to secure corrugated metal panels to roof decks while accommodating thermal expansion—a critical feature that prevents panels from buckling as temperatures rise and fall. Unlike standard screws or nails, which can create stress points and leak over time, corrugated roof clips distribute weight evenly across panels, creating a more stable connection.

Their importance becomes clear in challenging conditions:

- High winds: Clips with strong pull-out strength (500+ lbs) prevent panels from lifting.

- Heavy snow: Reinforced clips support snow loads without bending.

- Coastal areas: Rust-resistant materials avoid corrosion from salt air.

In short, a quality metal roof clip series isn’t an afterthought—it’s the foundation of a reliable corrugated roof.

How to Choose the Right Corrugated Metal Roof Clip Series

Not all clip series are created equal. The best choice depends on your roof type, climate, and project scope. Use this checklist to narrow down your options:

1. Material: Aluminum vs. Steel

The material of your clips directly impacts durability and cost:

- Aluminum clips: Lightweight, rust-proof, and easy to install. Ideal for residential roofs, coastal regions, or projects where weight is a concern. They’re less strong than steel but sufficient for most non-commercial applications.

- Steel clips: Available in galvanized (zinc-coated) or stainless steel options. Galvanized steel offers affordability and basic corrosion resistance, while stainless steel is premium—perfect for commercial roofs, heavy snow zones, or industrial settings. Steel clips have higher pull-out strength (600+ lbs) than aluminum.

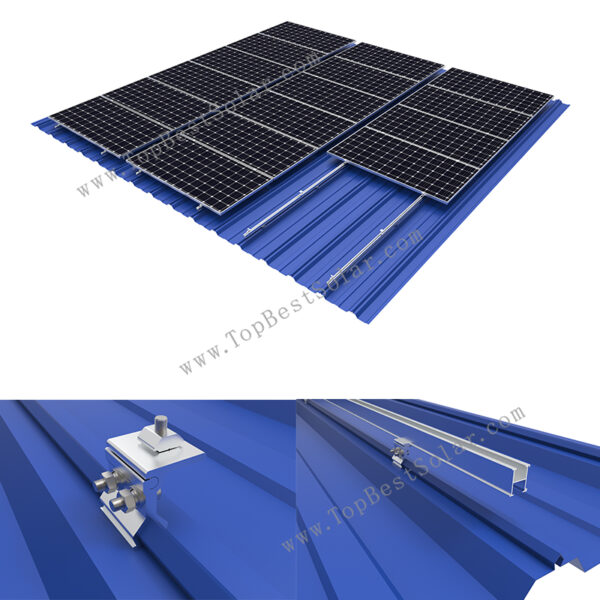

Pro tip: For solar panel installations on corrugated roofs, look for solar mounting metal roof clips—these have pre-drilled holes to simplify attaching panels without damaging the roof.

2. Match the Clip to Your Roof Profile

Corrugated roofs come in different profiles (e.g., 7/8” corrugated, 1-1/4” corrugated), and clips must fit the panel’s ridges to create a tight seal. Most manufacturers label their clip series by compatible profiles (e.g., “Series A: For 7/8” Corrugated Panels”).

If you have a standing seam metal roof (a popular variation of corrugated roofing), opt for standing seam-specific clips—these attach to the seams rather than penetrating the panels, reducing leak risk.

3. Consider Climate and Load Requirements

Your local weather should dictate clip strength:

- Hurricane-prone areas: Choose clips tested to withstand 130+ mph winds (look for ASTM D3161 certification).

- Snowy regions: Select clips rated for 20+ lbs/sq ft snow load.

- Hot climates: Clips with thermal expansion gaps prevent panels from warping in temperature swings.

4. Installation Ease: DIY vs. Professional

For DIY homeowners, look for easy-install corrugated roof clips with pre-assembled parts and clear instructions. Professional contractors may prefer heavy-duty clips that require specialized tools but offer superior stability for large-scale projects.

Top Corrugated Metal Roof Clip Series

Based on durability, versatility, and customer reviews, these three clip series stand out for residential and commercial use:

1. EcoClip Pro Series (Aluminum)

Designed for residential and light commercial roofs, the EcoClip Pro Series is a favorite among DIYers and contractors alike. Made from 6061 aluminum, these clips are 100% rust-proof and compatible with 7/8” and 1” corrugated panels. Key features include:

- Pre-drilled holes for quick installation.

- Thermal expansion slots to prevent warping.

- Rated for 120 mph winds and 15 lbs/sq ft snow load.

- Ideal for coastal homes and solar panel mounting.

2. SteelGuard Max Series (Galvanized Steel)

For heavy-duty commercial projects, the SteelGuard Max Series delivers unbeatable strength. Constructed from 18-gauge galvanized steel, these clips are built for warehouses, barns, and industrial facilities. Highlights:

- 650 lbs pull-out strength (ASTM tested).

- Compatible with 1-1/4” corrugated and standing seam panels.

- Resists corrosion for 20+ years.

- Rated for 25 lbs/sq ft snow load and 140 mph winds.

3. CoastalShield SS Series (Stainless Steel)

The CoastalShield SS Series is the premium choice for saltwater environments and high-end residential roofs. Made from 316 stainless steel, it offers maximum corrosion resistance and aesthetics. Features:

- Polished finish that complements metal roof aesthetics.

- Fits all standard corrugated profiles.

- Lifetime warranty against rust and failure.

- Suitable for luxury homes, marinas, and coastal businesses.

Installation Tips for Corrugated Metal Roof Clips

Even the best clip series will fail if installed incorrectly. Follow these best practices:

- Space clips properly: Install clips 6–12 inches apart along panel ridges—closer spacing for high-wind areas.

- Avoid over-tightening: Use a torque wrench to fasten clips to the manufacturer’s specifications (typically 15–20 ft-lbs). Over-tightening crushes panels and reduces flexibility.

- Seal gaps: Apply a bead of roof caulk around clip bases to prevent water infiltration.

- Inspect before finishing: Check that clips are aligned with panel ridges and that no panels are misaligned.

For solar installations, pair your clips with compatible mounting brackets to ensure panels are secured without damaging the roof structure.

Maintenance and Longevity: Getting the Most From Your Clip Series

A quality corrugated metal roof clip series can last 30+ years with minimal maintenance. To extend their lifespan:

- Annual inspections: Check for loose clips, rust (on steel models), or caulk deterioration.

- Clean regularly: Remove debris from clip bases to prevent water buildup.

- Replace damaged clips promptly: A single faulty clip can compromise an entire panel—replace with the same series to maintain compatibility.

Final Thoughts: Invest in Quality for a Secure Roof

Your corrugated metal roof is only as strong as its clips. By choosing the right metal roof clip series—matched to your roof type, climate, and project needs—you’ll avoid costly repairs and ensure your roof lasts decades. Whether you opt for the budget-friendly EcoClip Pro, heavy-duty SteelGuard Max, or corrosion-resistant CoastalShield SS, prioritize quality over price—your roof (and wallet) will thank you.

Ready to find the perfect clip series for your project? Contact our team for a free consultation, or browse our wholesale corrugated roof clips for bulk pricing on commercial orders.