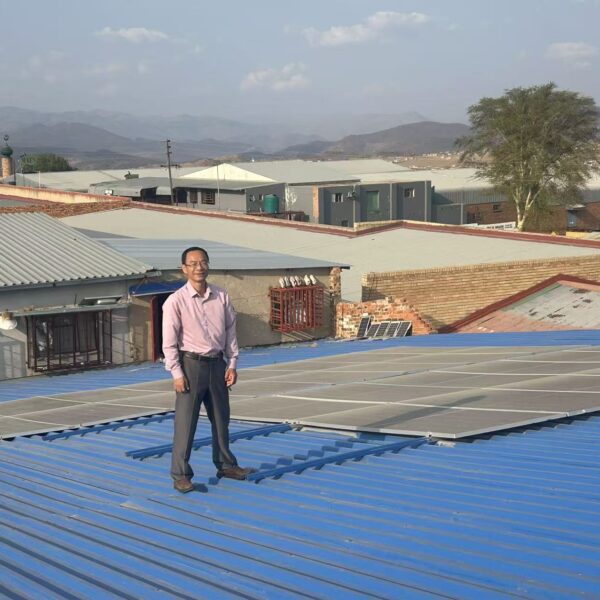

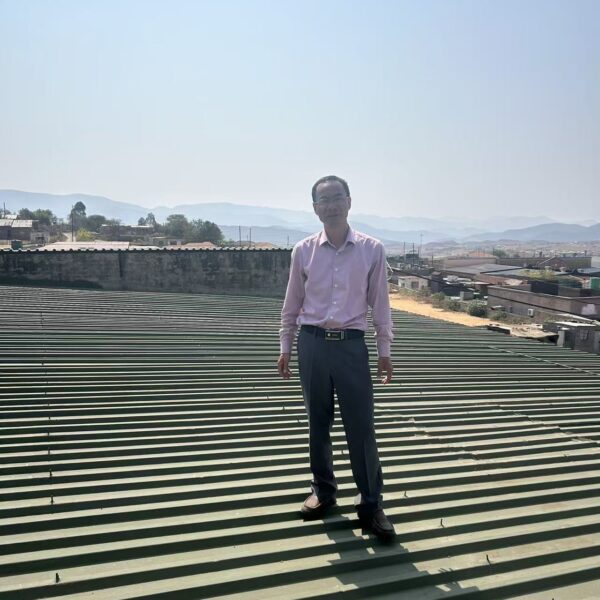

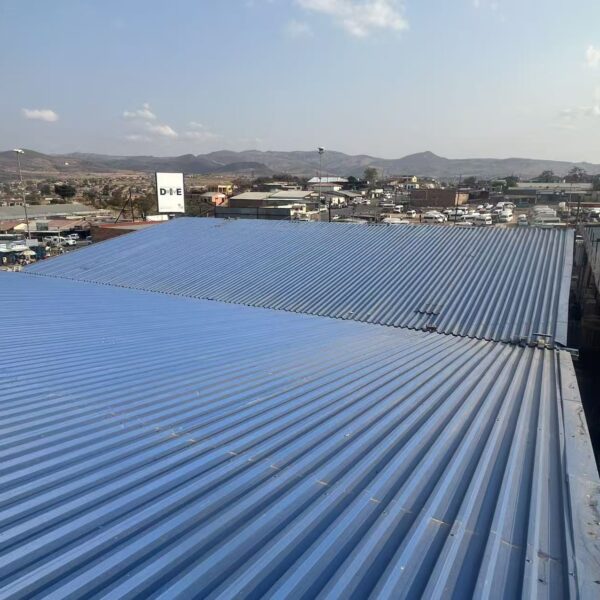

1.Why does your team conduct on-site visits to rooftop solar projects (like the one in South Africa)?

On-site visits address regional variations in rooftop types (e.g., South Africa’s common concrete/clay tiles), local climate conditions (wind loads, UV exposure), and site-specific constraints (batten spacing, roof integrity).This ensures our solar mounting solutions (e.g., ZAM Steel Hook Series) are tailored to the actual project environment—not just theoretical designs—reducing post-installation issues.

2.What specific tasks do you perform during on-site rooftop surveys?

Our on-site work includes:

– Precise rooftop dimension measurements (to align with solar mounting bracket specs);

– Assessment of roof structure, load-bearing capacity, and waterproofing conditions;

– Real-time discussions with the design team to adjust drawings (e.g., hook placement, rail spacing);

3.What’s the advantage of discussing design drawings with the design team on-site?

On-site drawing reviews let us adjust plans *immediately* based on real rooftop conditions (e.g., unexpected tile profiles or structural gaps).This eliminates delays from back-and-forth remote revisions, ensures the mounting system fits perfectly, and speeds up the installation timeline for your project.

4.Will you provide this on-site support for projects outside South Africa?

Yes.We offer on-site surveys and design collaboration for projects across our target markets (South Africa).For smaller-scale projects, we combine remote 3D modeling with on-site photos/measurements;for large commercial projects, our technical team will deploy to your location directly.