1.What is a solar grounding clip?

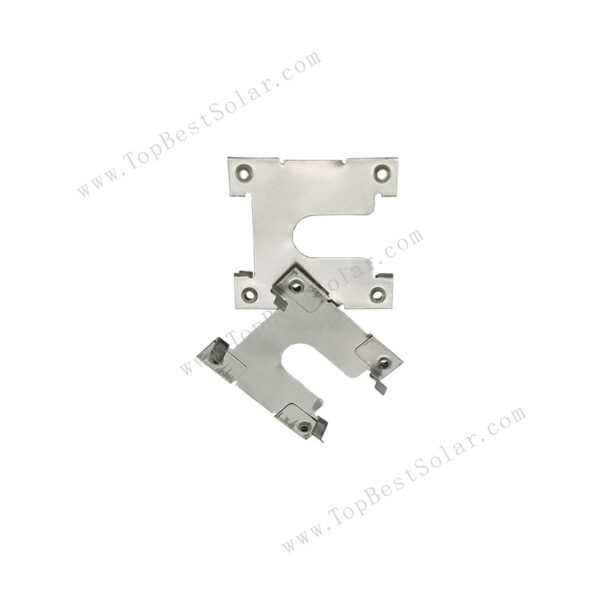

A solar grounding clip is an EGC (Equipment Grounding Conductor) component that establishes an electrical path between PV modules, mounting rails, and the earth . Made typically from SUS304 stainless steel , its serrated teeth pierce anodized aluminum surfaces to create gas-tight conductivity .

2.Why are solar grounding clips necessary?

They prevent three critical risks:

– Safety hazards: Divert lightning strikes and fault currents to avoid electric shock/fire

– Equipment damage: Protect inverters and modules from power surges

3.How many grounding clips do I need per solar panel?

Generally, you’ll need one solar grounding clip per module-to-rail connection—this ensures each panel is securely grounded to the mounting structure.However, some systems require two clips per panel for redundancy, especially in high-lightning regions (e.g., Florida, Southeast Asia) where storm-related surges are more frequent.For example, if your PV modules use two mounting rails (a common residential setup), two clips per panel may be recommended to create a backup path. Always follow the manufacturer’s specs for your specific PV model.

4.What’s the correct installation method?

Follow these steps to install a solar grounding clip properly:

1)Position the clip between the PV module frame and aluminum mounting rail, ensuring it’s centered over the rail’s grounding point.

2)Align the clip with mid-clamps (used to secure panels to rails) and apply the proper torque (usually 8–12 N·m, per clip specs) to drive the serrated teeth through the anodized aluminum layer—this guarantees a solid electrical connection.

3)Avoid self-tapping screws here: they can loosen over time. Instead, use crimped connections for long-term reliability.

4)Test continuity with a multimeter post-installation to confirm the clip is conducting electricity (aim for a resistance reading below 1 ohm).

5.Are all solar grounding clips the same?

No—solar grounding clips vary by design, load capacity, and warranty to fit different system needs:

– Model types: Common options include the SPC-GW-05 (universal fit for most PV frames), SPC-GW-17 (frame-specific for thin-film modules), and 4A washer-style clips (for retrofitting older systems).

– Load ratings: Most clips handle 60m/s wind loads (equivalent to 134 mph) and 1.4kN/m² snow loads—enough for most residential and light commercial setups.

– Warranty: Warranties range from 10–20 years.

6.How do I maintain grounding clips?

Regular maintenance keeps solar grounding clips working effectively:

– Inspect clips quarterly for corrosion (common in coastal areas) or loose connections—tighten any clips that shift due to weather.

– Test conductivity annually with a multimeter; if readings exceed 1 ohm, clean the clip’s teeth with a wire brush to remove dirt or oxidation.

– Replace damaged clips immediately: While SUS304 stainless steel resists rust, physical damage (e.g., from falling debris) can break the grounding path.

7.Can I use aluminum instead of stainless steel clips?

No—aluminum is not suitable for solar grounding clips. Aluminum corrodes much faster than SUS304 stainless steel, especially in humid or coastal areas (where salt air accelerates rusting). A corroded aluminum clip will break the grounding path within 3–5 years, leaving your system unprotected. In contrast, SUS304 stainless steel ensures a 25-year service life, matching the lifespan of most PV modules. For example, a coastal home using aluminum clips may need full replacement after 4 years, while stainless steel clips would remain functional.

If you’re interested in our components or solar mounting systems, we’d love to provide and discuss with you about them.

Contact us and we will be in touch with you shortly.

More details for you. Contact us by our website: